Product Description

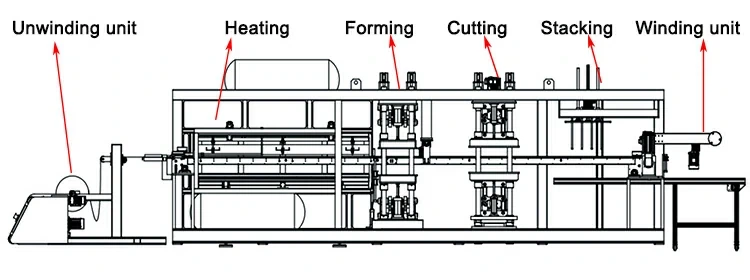

Although this Cup Lid Thermal Vaccum Forming Machine runs at a quite fast speed, 30 times per minute at most, the noise is comparatively low. Though the structure is complex, it is still easy to operate and shows high reliability. A Servo-control system is applied to all the machines. Moreover, the advanced automatic system is also adopted. the Cup Cover Thermal Vaccum Forming Machine runs perfectly in the processing of PP, PS, BOPS, PET, and PVC production.

With the following three optimized parts, the replacement can be finished in a quite short time, and the productivity is greatly improved. The three parts are as follows: the newly-designed mold replacement structure, a simplified replacement system, which is optimized according to human body ergonomics, and a cutting knife punching and stacking device.

Parameter

| Model | HG-DM60 |

| Machine Type | Three Stations Auto PP Cup Cover Lid Thermal Vaccum Forming Machine |

| Applicable raw materials |

PP, PS, PET, PVC, OPS, degradable materials, PLA, etc. |

| Forming method | Positive and negative pressure forming |

| The maximum forming mold area | Width 780×Length 600mm |

| The minimum molding die area | 420×300mm |

| Air pressure | 7 Bar |

| Travel depth | 150 mm |

| Formed depth | 130 mm |

| Maximum sheet width | 450-810mm |

| Applicable sheet thickness | 0.15-2.0mm |

| Stacking mechanism | Hanging point stacking |

| Rated power of the whole machine | 120 KW |

| Heating power | 25-55kw |

|

Weight |

14 T |

| Dimension | 12m*2.8m*2.6m |

| Power access | 380V/50HZ (three-phase five-wire) |

Thermal Vaccum Forming Machine Detail

Feature

1. Three Stations Cup Lid Thermal Vaccum Forming Machine uses a microcomputer touch screen man-machine interface control system, the operation is intuitive and easy to operate, convenient, and easy maintenance.

2. The vertical pull tab design is adopted. The pull tab is very fast, average, and stable, which shortens the time taken by the pull tab. It is more adaptable for environmentally friendly materials and can also reduce power consumption and ensure product molding quality.

3. Compared with the famous brand machines in the market, we form a larger layout, and our working efficiency is a little slower than theirs, but we have a large molding area, and we can produce many more products in the same mold, so that the efficiency is comparable.

About Us

Our company is a professional manufacturer of Three Stations Auto PP Cup Cover Lid Thermal Vaccum Forming Machine. We have lots of automatic cutting machines, embossing machines, and plastic thermoforming machines for sale. This is forming+cutting parts made in Honggang factory then deliver to our another two thermoforming machine factories (in Dongguan city)

Our advantages:

1. The original Three Stations Auto PP Cup Cover Lid Thermal Vaccum Forming Machine manufacturer

2. Honggang specializes in forming+ cutting parts for 29 years

3. Honggang provides forming+cutting parts for their 3 stations machine for other vacuum forming manufacturers

Hot Tags: Three Stations Auto PP Cup Cover Lid Thermal Vaccum Forming Machine, China, suppliers, manufacturers, fatory, automatic, price, for sale